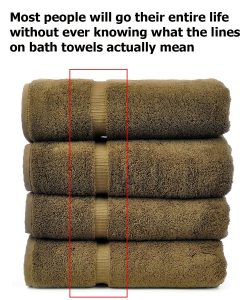

Bath towels are one of those everyday items we tend to overlook, even though we use them daily. We reach for them after showers, wrap ourselves in them for warmth, and toss them in the wash without giving much thought to what makes one towel better than another. But if you’ve ever paused to really look at a towel, you may have noticed subtle lines or patterns woven into the fabric. At first glance, they might just seem like decorative details—something added to enhance the towel’s appearance. However, those lines are far from just visual flair. They’re actually the result of thoughtful engineering and design choices that serve functional purposes, making the towel more efficient, durable, and pleasant to use. Once you understand the reasons behind these subtle design choices, you’ll start to see bath towels in a whole new light.

What many people don’t realize is that those woven lines are created through specific weaving techniques that improve how the towel performs in your daily routine. These aren’t random or decorative by chance—they’re there to enhance absorbency, increase structural integrity, and influence the tactile experience. That’s right, something as simple as a line of stitching or a change in texture can influence how well your towel works and how long it lasts. It’s proof that even the most ordinary household items can be more complex and better engineered than we assume.

Let’s start with one of the most essential functions of any bath towel: water absorption. After all, a towel’s main job is to dry you off as quickly and effectively as possible. Those lines you see actually help the towel do just that. The weaving techniques used to create these lines often involve changing the texture or density of the fabric in certain areas, which can increase the towel’s surface area. That increase means the towel has more contact points to soak up water from your skin. It’s a small design element with a big impact—improving how dry you feel after a shower and reducing the amount of time you spend rubbing your skin to get dry.

Additionally, those lines can help improve airflow when the towel is hung up to dry. Think about it: when a towel dries faster, it’s less likely to develop that unpleasant musty smell. That’s because moisture doesn’t sit in the fibers as long. These woven channels allow air to circulate more easily, which helps moisture evaporate quicker. The result? A towel that’s fresher for longer and ready to use again in less time. In some cases, the lines even act as natural guides for folding and hanging, making it easier to keep your bathroom looking tidy and your linen closet neatly organized.

Another benefit comes in the form of tread lines, which are the raised ridges you can sometimes feel when running your hand across the towel. These lines aren’t just there to add texture or visual interest. They’re carefully crafted using weaving methods that actually reinforce the towel’s structure. That reinforcement helps the towel maintain its shape and resist the kind of wear and tear that comes from frequent use and repeated washing. Over time, towels without this kind of structural support can become thin, fray at the edges, or lose their plush feel. But towels with tread lines tend to stay soft and maintain their loft for much longer. Think of these lines as invisible reinforcements—like tiny support beams built right into the fabric, quietly doing their job to extend the life of your towel.

A related technique responsible for many of the patterns and lines you see is known as the dobby weave. This weaving method involves using a special loom attachment to create small, geometric patterns that are embedded into the fabric. While these designs may look ornamental, they’re also incredibly practical. The dobby weave creates a tightly structured fabric that holds up better over time. It resists pulling, stretching, and warping—common problems that lead to towels losing their shape. If you’ve ever owned a towel that seemed to maintain its form and function after countless washes, there’s a strong chance a dobby weave played a role in that performance. It’s another example of how form and function blend seamlessly in quality textiles.

You’ve probably also noticed that many towels have a distinct border along the edges. These are often referred to as dobby borders, and they serve more than just an aesthetic purpose. Yes, they give the towel a crisp, finished look, but they also play a vital role in extending the towel’s lifespan. These borders are typically woven with tighter and more durable threads than the rest of the towel. This denser weaving at the edges helps to prevent fraying and unraveling—two of the most common problems that can ruin a towel before its time. In a way, the dobby border acts like a frame around a painting—it strengthens the outer edges, giving the entire towel more structure and support, especially during machine washing and drying cycles.

All of this attention to detail might seem excessive for something as seemingly simple as a towel, but that’s exactly the point. The next time you reach for your bath towel, take a closer look. Feel the raised tread lines, notice the patterns woven into the fabric, and appreciate the sturdy border along the edge. Every one of those elements was added with purpose. They’re not just there to make the towel look pretty or stylish. They exist to enhance your daily experience, to make drying off more effective, and to ensure that your towel stays in good condition use after use. It’s easy to think of towels as disposable or replaceable, but the truth is that a well-made towel can last years when designed with intention and care. So the next time you wrap yourself in a soft, absorbent towel, you’ll know that what you’re feeling is the result of thoughtful craftsmanship—hidden details working hard behind the scenes to improve your everyday life.